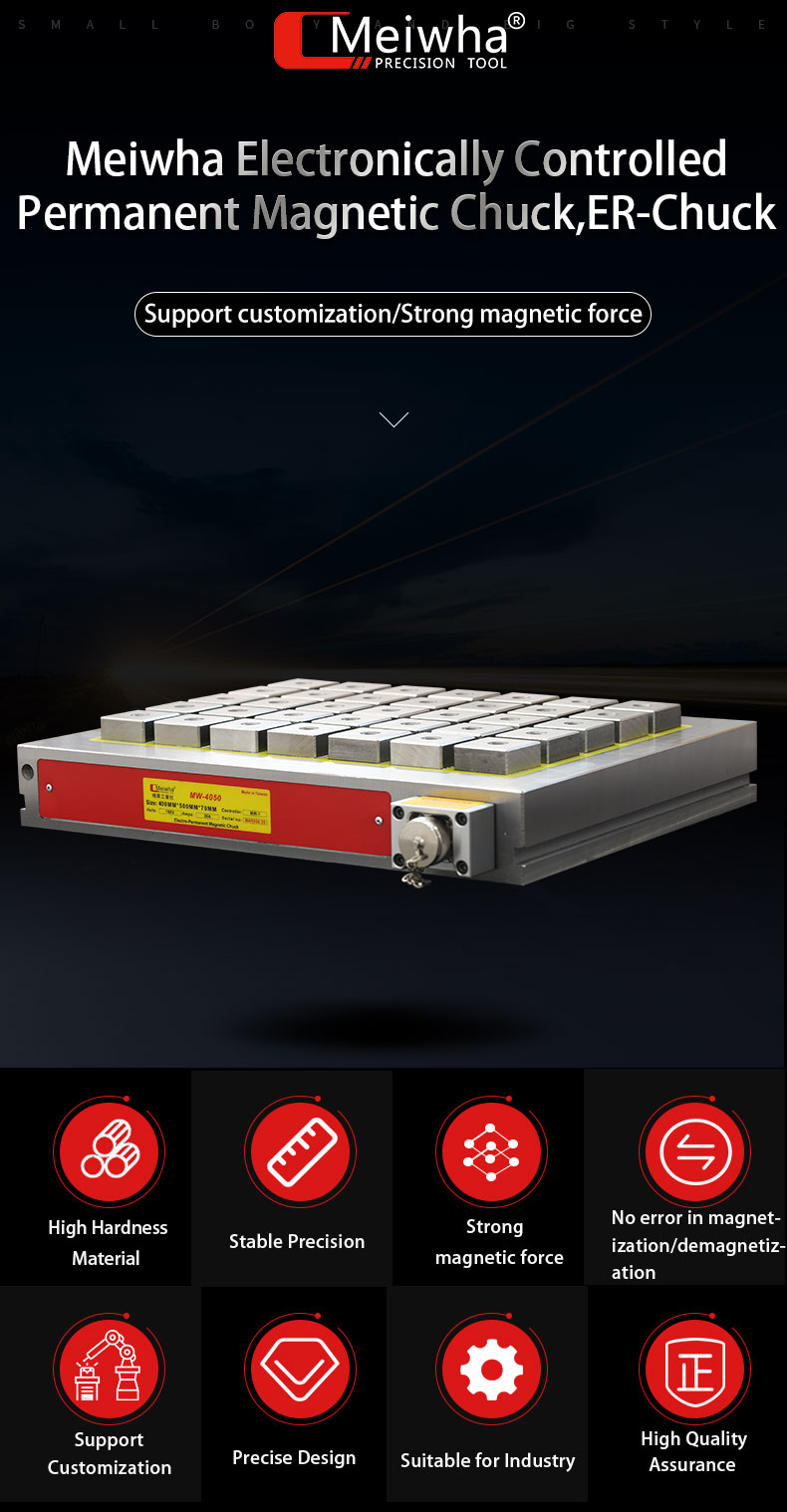

Amashanyarazi Yama Magnetic Chucks Kumashanyarazi ya CNC

Amashanyarazi ahoraho yamashanyarazinigikoresho cyiza cya magnetiki gifata muri iki gihe, gikoresha amashanyarazi kugirango "fungura kandi ufunge". Nibyiza cyane kandi byizewe mugihe igihangano gikururwa na magnetiki chuck mubikorwa. Nyuma yo gukurura ibihangano bya magnetisme, chuck ya magneti ifata magnetism burundu. "Gufungura no gufunga" igihe kiri munsi yisegonda 1, impanuka yumuriro itwara ingufu nke, chuck ya magnetique ntabwo izaba ihindagurika ryumuriro. ikoreshwa cyane mugukata ibihangano mugihe ikozwe nimashini yo gusya na CNC.

Ibiranga ibyiza

1 Iyo clamping imaze kuboneka gutunganya impande eshanu, ibihangano byemerewe kuba binini kuruta urubuga rukora.

2 Uzigame 50% -90% igice cyo gutanga, kunoza imikorere yumurimo nigikoresho cyimashini, imbaraga zumurimo muke.

3 Ntabwo bisabwa guhindura ibikoresho byimashini cyangwa umurongo wo kubyaza umusaruro, nkuko igihangano cyatsindagirijwe kimwe, igihangano ntigishobora guhinduka, nta kunyeganyega mubikorwa. Ongera ubuzima bwakazi bwaibikoresho byo gukata.

4 Magnetic chuck irakoreshwa mugukata ibice bitandukanye munsi yo gusya kuremereye cyangwa kwihuta cyane muburyo butambitse kandi buhagaritse, biranakoreshwa mugukata, bidasanzwe, gufunga bigoye, icyiciro hamwe nibikorwa byihariye. Irakoreshwa muburyo bukomeye no kurangiza gutunganya.

5 Imbaraga zihoraho, ntizisaba amashanyarazi mugihe iri mumashanyarazi, nta mirasire yumurongo wa magneti, nta kintu cyo gushyushya.

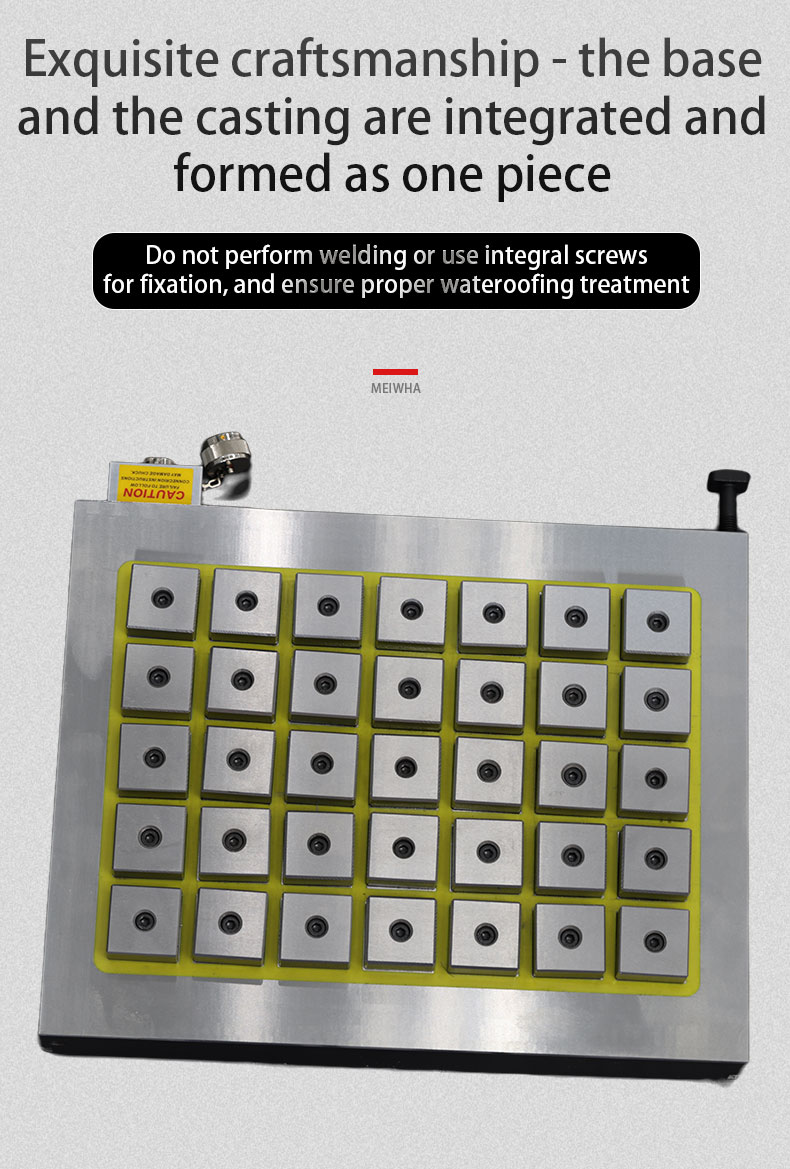

Ukuri kwinshi: Kubaka kuva mono-block icyuma

Nta Heat Generation: Irasaba kugenzura kuzimya "On" cyangwa "Off", hanyuma ucomeke kugirango ukoreshwe

Kugwiza Igice Cyinshi: Igikoresho cyo hejuru cyemerera igihangano gito kuruta isura ya magnetiki kugirango ikorwe kumpande 5

Vacuum Yuzuye Byuzuye: Vacuum yuzuye resin ya dielectric ihinduka blok ikomeye idafite ubusa cyangwa ibice byimuka

Imbaraga zisumba izindi: Sisitemu ebyiri ya magnet itanga imbaraga zo gukurura imbaraga kuri pole couple ya 1650 lbf kugirango ifate byinshi

Palletizing: Yerekana kuri sisitemu iyo ari yo yose. Imbaraga zisabwa gusa kugirango uhindure magnet "On" cyangwa "Off"

Ihinduka: Igikorwa kimwe gifata igisubizo kubice byinshi bya geometrie

Umutekano: Ntabwo byatewe no kunanirwa kwamashanyarazi kandi bifunze neza kandi bikozwe mumazi